The Buzz on Aws Cwi

Not known Facts About Aws Cwi

Table of ContentsThe smart Trick of Aws Cwi That Nobody is Talking AboutGetting My Aws Cwi To WorkThe Best Strategy To Use For Aws CwiOur Aws Cwi PDFsNot known Details About Aws Cwi

Have you ever took into consideration a career as a welding inspector? A welding examination qualification is not just an excellent success, it verifies your abilities in the welding industry.

Coming To Be a Certified Welding Examiner shows your commitment to expanding within the welding sector. This certification is one that ought to not and will not be neglected! As a CWI, you'll be able to benefit from a variety of different opportunities among sector professionals.

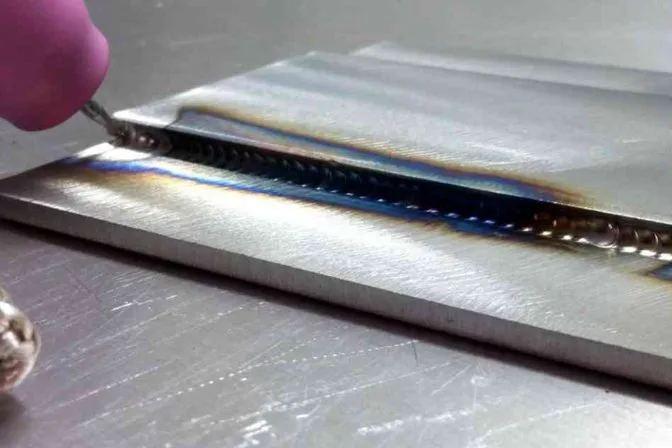

Qualified Weld Inspectors are an incredibly helpful and important asset for metal producers. Their visibility is quite beneficial for any kind of firm working with the producers that bring them on board. As you might know, welding is among one of the most intricate solutions within the metal fabrication sector. The outcome of every welding task is highly dependent upon individual welder ability.

Our Aws Cwi Ideas

There's no question that CWIs assistance to support higher levels of consistency and top quality to the welding departments they look after. This post gives a quick review of the main advantages of functioning with a metal manufacture business that uses certified weld assessors. It's not shocking that most prominent markets will require you to employ certified welding assessors to manage welding.

Qualified welding examiners have years of experience and thus, they recognize the subtleties of conformity with welding codes. Following the welding process, CWIs can carry out a series of examination to examine the quality of a weld, consisting of visual assessment, warm treatment and a hydrostatic test. CWI Welding Inspector. They can additionally make the proper changes to the pre-weld prep work and the in-weld treatments as necessary

An internal licensed welding assessor will certainly have the ability to ensure that your task is customized to all the requirements of relevant welding codes, ensuring its top quality. Welding inspectors can assess welding treatment requirements, building and welding strategies, equipment calibration and welding products. A welding inspectors ability to give welding procedure requirements offers the steel fabrication company a considerable side of the competition, enabling producers to design welds that best suit private components, instead of utilizing reliable welds.

Some Known Factual Statements About Aws Cwi

As formerly pointed out, a CWI is not only liable fore writing the procedures for the weld, but additionally the quality-check testing treatments. http://peterjackson.mee.nu/where_i_work#c2362. Past that, welding assessors function to make certain that equipment is properly prepped for the work which welders are able to complete their welds with proficiency (Welding Inspection Agency). A qualified welding inspector will have had several years of experience, which a metal construction firm can take advantage of to make sure outstanding results for all manufacture tasks that involve welding

This is why it's essential to locate a welding business with a skilled and very trained internal qualified welding inspector on staff. CAMM metals is such a service, so call us today if you have a future project that calls for quality customized welding! It's clear that a customized metal manufacture supplier with in-house CWIs has actually committed to buying the quality of its welds.

Here at CAMM Metals, after the welding part of the project is total, we supply numerous internal solutions. These solutions consist of weld inspection with dye penetrant, acid cleaning and polishing of stainless steel welds.

For those clients who require certified welds, we can certify our welds to AWS D1.1 & AWS D1.6.

The Basic Principles Of Aws Cwi

It's important to note that numerous employers don't constantly call for welders to be certified. The main difference is that certified welders have written records of their test outcomes and their efficiency is regularly kept an eye on with regular assessment( s) being part of the efficiency record for each welder.

Prior to taking the examination all PFS welders are trained, if required, in the real welding process that they will certainly be utilizing and they will need to have a functioning expertise of the welding tools, welding palatable and the product to be welded. Successfully passing one examination will allow the welder to work on many kinds of fabrications yet will certainly not enable him to deal with all sorts of manufacture as there are certification varies imposed for every test setup.

Crucial variables include however are not limited to product type, consumable kind, material density and welding position. and so on. After the welder has finished his examination my review here plate or pipeline the weld is examined utilizing the following NDE procedures: Visual Evaluation X-Ray Fluid Penetrant Testing In some cases, the weld is additionally destructively tested.

Aws Cwi - Questions

PFS completes this making use of a continuity record that information all welds that a welder makes. If a welder does not make use of the welding procedure in a 6-month duration, after that they shall be requalified because procedure. The benefits to making use of an accreditation system are several but the significant benefits are: It verifies the ability of an individual to execute according to a certified welding procedure spec (WPS) to generate an excellent weld.